Concentrator modules

PV systems with concentrators may provide economical advantages, if high-efficiency multi-junction III-V cells are combined with cheap optical concentrators providing high concentration ratio (500-1000x and above). A promising way for concentrator system development is a concept of small-aperture area submodules in PV module design. In this case the advantages of a concentrator system (rise in efficiency, saving the semiconductor and structural materials) may be realized at retention (in the whole) of a distributed character of sunlight conversion and heat dissipation-similar to the case of systems without concentration.

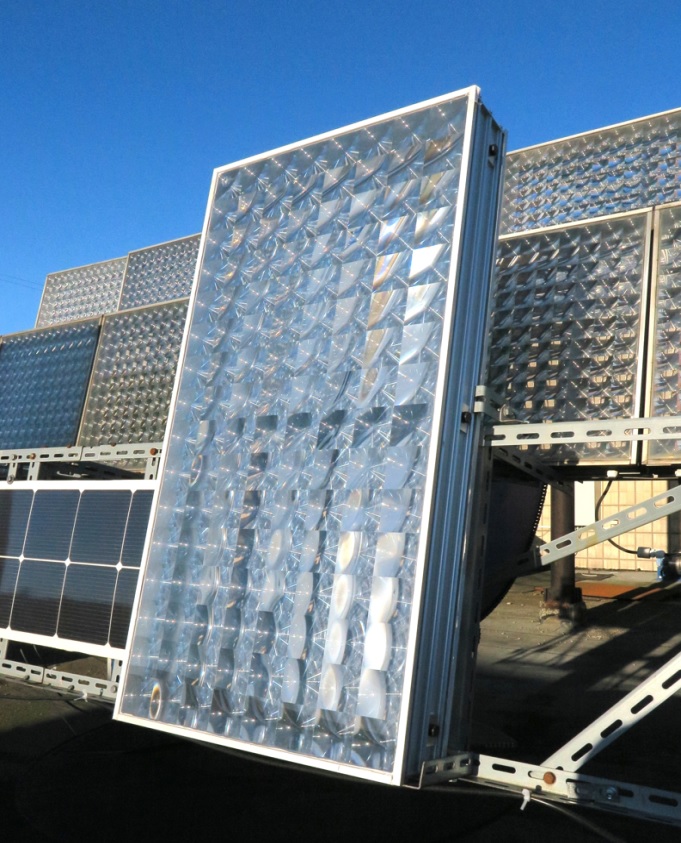

Different types of concentrator modules have been designed and manufactured for space and terrestrial applications in PV Lab at Ioffe Institute. In the modules, refractive-type concentrators (Fresnel lenses) have a composite structure: microprisms are formed from transparent silicone rubber contacting with front glass sheet as a protective superstrate. The lenses are arranged on a common superstrate in a view of lens panel. The cells as small as 2 or 1.2 mm in designated area diameter operating at concentration ratios 500-1000x are intended for used in the PV modules. Developed formation process allows fabricating the lens panels of total area 0.5 x 0.5 m2.

|

|

|

| Solar cell, mounted to the copper heatsink. | Terrestrial concentrator PV modules with composite 12x12 lens panel (50x50 cm). |

The panel of primary Fresnel lenses is arranged as a number of identical strings of six lenses in each string. In regard to the panel of cells, it is arranged as a corresponding number of identical units, where six cells and one by-pass diode are mounted in parallel circuit on a common heat sink.

|

| Individual lens string and cell unit, intended for work with one of the lens strings. |

High accuracy of tracking to the sun is a specific feature of the high-concentration PV method. During last year an improved version of the 1 kWp tracker was designed and built in the Ioffe Institute. In construction of the tracker the cheapest structural materials have been used, such as perforated steel channels and angles. The possibilities for transportation have been considered in the tracker design. For this, all members and parts are no longer than 2 meters and no wider than half of meter . At the same time, necessary rigidity is completely ensured owing to structural features of the tracker frames.

Indoor overall conversion efficiency measurement by means of a specially developed flash solar simulator with large aperture area Fresnel-type collimator

|

|

|

|

| Sun tracker with concentrator PV modules installed on the roof of the Ioffe Institute. | Sun tracker parts ready for transportation. |

The tracker is equipped with main (accurate) sensor and additional one, both equipped with tandem-type III-V cells and operating as a part of a close-loop system. Main sensor can align the tracker with the sun to within 0.05 degree of arc accuracy with acceptance angles of 70 . Additional sensor makes wider the "East/West" turning angle (up to 270 ). Both sensors are mounted on the suspended frame together with PV modules. An advantage of the developed sensors is protection from influences caused by illumination level changes due to light reflections from various objects during a day and presence of clouds. For this, main sensor includes two sub-channels in both horizontal and vertical channels. Differential signals are generated in correspondence with misalignments of the tracker to the sun in azimuth and elevation. The shadowing tube limits acceptance angles of the cells in accurate sub-channels to 1-2. Photocurrents generated in accurate sub-channels give rise to switching all the other cells off. Electronic board includes solid-state relays, motor microdrives and voltage-current measuring units. Simplicity and consumption of current as low as 45 microamperes from a rechargeable 12V-battery in stand-by regime are the positive features of the developed electronic board.

|

| Main sun sensor installed together with concentrator PV array powering the tracker. |

Compact sealed 12V battery with capacity of 5 A hours serves as a buffer power source for automatic operation of the tracker. Charging the battery is carried out from a small-size concentrator PV array installed on the suspended frame of the tracker together with main sun sensor. Overall power consumption for tracking including West-East returns was estimated to be no more than 0.2% of installed power.

Recent advances in the research and development of Concentrator photovoltaics modules (CPVM) in the PV Lab:

Two types of CPVM were developed and studied: with Fresnel lenses 60x60 with a focal length of 105 mm (CPVM-60) and modules with Fresnel lenses 120x120 mm in size with a focal length of 220 mm (CPVM-120). In both types of CPVMs, three-stage solar cells based on GaInP / GaAs / Ge heterostructures with a solar radiation conversion efficiency of more than 42% were used as radiation receivers.

1. Concentrator photovoltaic modules CPVM-60

In the CPVM-60 design with Fresnel lenses 60x60 mm the lens panels contain a matrix of 128 lenses is formed on glass 480x960x4 mm. Three-junction GaInP/GaAs/Ge solar cells of 3x3 mm were installed on the power generating panels for receiving radiation at the focus of the lenses. Silicate glass sheet was used as the main structural material of the power generating panels and for the front panel of the Fresnel lenses. Glass is at the same time the mechanical basis of the power generating panel, and the integral protective window for all solar cells in the EGP

2. Concentrator photovoltaic modules CPVM-120

In the CPVM-120 module the lens panel contains 32 Fresnel lenses 120x120 mm. The power generating board contains 32 chips of three-junction solar cells 5.5x6 mm. They are located on the inner side of the metal base. Each lens focuses solar radiation onto the surface of the PV cell. To increase the conversion efficiency of solar radiation and improve the misorientation characteristics of the concentrator modules, an element of secondary concentrating optics - a focusing cone - was installed above each solar cell.

3. Light volt-ampere characteristics of solar concentrator modules. The efficiency of the developed concentrator modules was measured using a pulsed solar radiation simulator at a temperature of 25C. During the time of the light pulse, the current-voltage characteristic of the module under study was recorded and the energy parameters of the modules were measured. When irradiated with a simulator of solar radiation (at an irradiance of 1000 W / m2), the maximum light conversion efficiency in the CPVM-60 module was 32.9% and the maximum generated electrical power was 151.6 W. The maximum efficiency of the CPVM-120 module was 32.3% and the maximum generated electrical power was - 149 W.

CPVM-60 at the installation for tracking the Sun.

CPVM-60 at the installation for tracking the Sun.